Perforation Applications – Industries and Use Cases

What Are Perforation Applications?

Definition and Process

Perforation is a controlled mechanical process that introduces a pattern of holes or openings into continuous web materials such as films, foils, paper, or laminates. It is typically performed inline using rotary perforation units equipped with needle, blade, or punch-type units working against a counter roller or dies. The geometry, density, and spacing of the holes are precisely defined to deliver specific functional effects while preserving the mechanical integrity of the material.

Types of Perforation

Micro-perforation:

Involves very fine, closely spaced holes (typically from tens to hundreds of microns) designed to regulate gas or moisture transmission without visibly altering the film. Micro-perforation can be achieved mechanically or through laser perforation, which allows exceptional accuracy, clean edges, and repeatable hole geometry — ideal for high-performance packaging and breathable films.

Example: laser-micro-perforated polyethylene films used to control respiration in fresh-produce packaging or to balance pressure in medical and pharmaceutical laminates.Macro-perforation:

Produces larger openings (generally above 1 mm) to enable functions such as air flow, drainage, or controlled tearing.

Example: macro-perforated shrink films for beverage multipacks or perforated membranes used in construction for ventilation and moisture release.

Industrial Applications of Perforation

From packaging and medical films to industrial and construction materials, perforation technology ensures smarter performance—combining efficiency, precision, and reliability to meet demanding production needs.

-

Perforation technology plays a vital role in chemical, pharmaceutical, and mining industries, where precise control of airflow, filtration, and separation is essential for product performance and process safety. In chemical processing, perforated films and membranes regulate gas exchange and vapor release with high consistency. In pharmaceuticals, micro-perforation ensures sterility, pressure equalization, and moisture control in sensitive packaging and production environments. In mining and raw material handling, durable macro-perforated materials improve filtration, dust control, and liquid separation under demanding conditions. Spark Machinery’s perforation systems combine accuracy, robustness, and process reliability, ensuring consistent results across diverse industrial operations.

-

Perforation technology enhances performance and functionality in packaging and food-processing applications. In packaging, it enables easy opening, controlled gas exchange, and freshness preservation through micro-perforated films—ideal for modified atmosphere packaging (MAP) and high-speed production lines. In food manufacturing, perforated materials support efficient drying, baking, and cooling, ensuring uniform airflow and consistent product quality. From produce packaging to industrial baking trays, Spark Machinery’s perforation systems deliver precise, hygienic, and reliable results that optimize both processing efficiency and product performance.

-

Perforation technology is widely applied in the automotive sector to enhance comfort, performance, and functionality across interior and technical components. Precision-perforated materials are used in seating, dashboards, and door panels to improve ventilation, acoustic absorption, and aesthetic quality. In manufacturing and assembly, technical films and foils with engineered perforation patterns support adhesion control, lamination, and protective surface release. Perforated membranes also enable controlled airflow, filtration, and moisture management in insulation and battery systems. Spark Machinery’s perforation systems deliver the precision, repeatability, and process stability required by automotive standards, ensuring high-quality results for both decorative and functional applications.

-

Perforation technology is essential in the production of agricultural films, especially mulch films, where precise control of air, moisture, and temperature directly influences crop growth and yield. Perforated mulch films enable regulated gas exchange, water permeability, and soil aeration, helping maintain optimal root-zone conditions while preventing excessive heat or moisture buildup. This improves seed germination, plant development, and soil health, while reducing the need for chemical treatments. Beyond mulching, micro- and macro-perforated agricultural films are also used in greenhouse covers, silage wraps, and soil fumigation films to manage humidity, condensation, and gas diffusion. Spark Machinery’s perforation systems deliver uniform hole geometry and reliable web control, ensuring consistent film quality and long-term field performance.

Benefits and Effects of Perforation

Perforation adds both technical performance and commercial value to films, foils, and laminates by enabling precise control over air, moisture, and mechanical behavior. It improves ventilation and airflow, helping regulate temperature and humidity in packaging, agricultural, and technical applications. Through accurate hole geometry, perforated materials provide selective filtration and barrier control, balancing breathability and protection. Controlled perforation lines also enable easy tearing or opening, enhancing user convenience without compromising strength.

In addition to functionality, perforation supports product differentiation through unique textures and visual effects, strengthening brand identity. It also contributes to energy efficiency and material optimization, improving drying, cooling, and process performance while reducing raw material use.

Spark Machinery’s perforation systems combine precision engineering and process reliability, delivering consistent quality and measurable performance advantages across diverse industries.

Suitable Materials for Perforation

Spark Machinery’s perforation systems are engineered to process a wide range of film-form materials, ensuring high precision, uniform hole geometry, and stable web handling across diverse production environments.

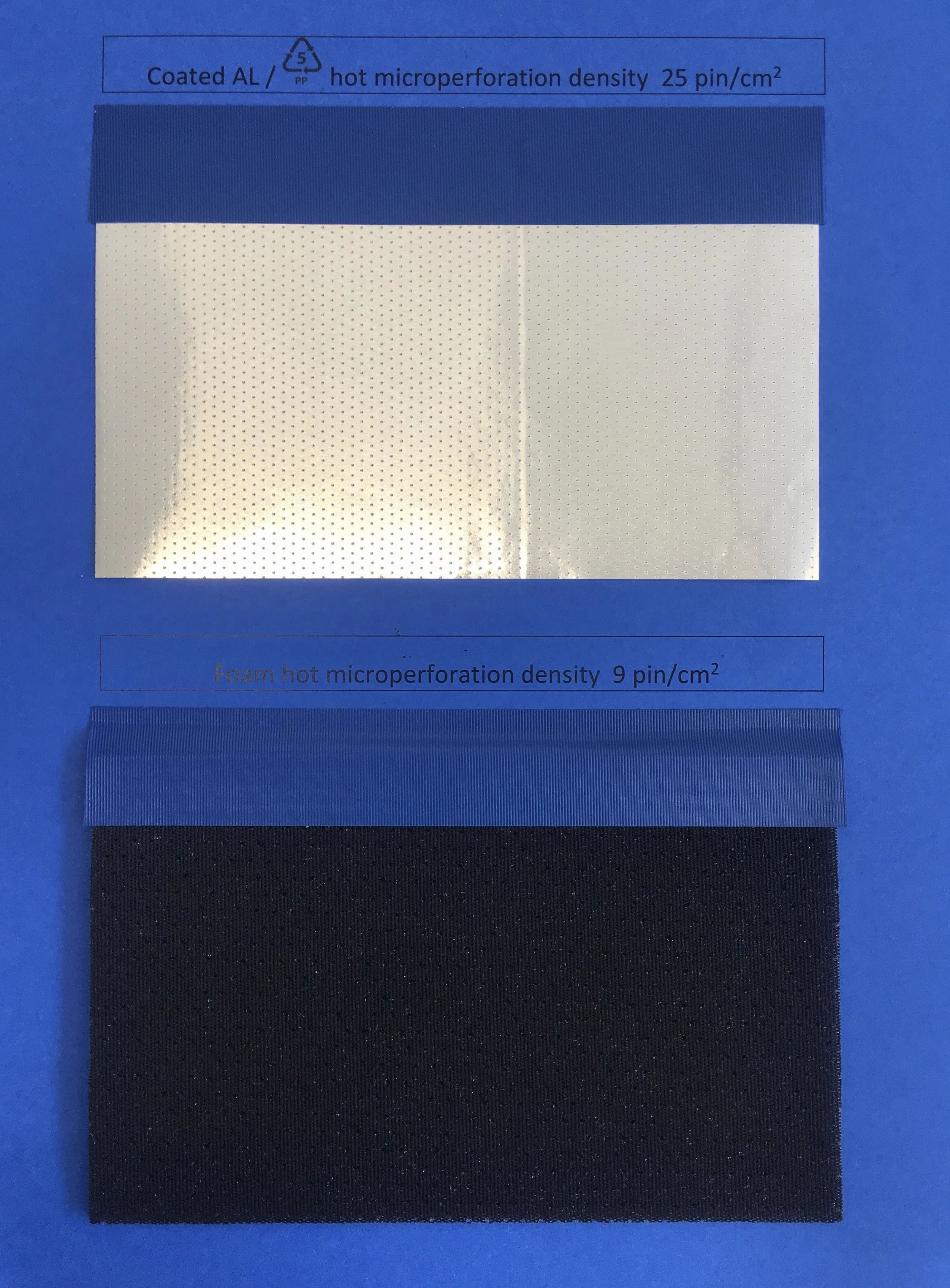

Polymeric films such as Polyethylene (PE) and Polypropylene (PP) are widely used in packaging, agricultural, and hygiene applications due to their flexibility, durability, and clean tearing behavior. Polyester (PET) and Polyamide (PA) films offer excellent dimensional stability, mechanical strength, and heat resistance, making them ideal for technical and barrier films. PVC, PVdC, and biodegradable films (e.g., PLA, starch-based blends) are used where precise permeability control and sustainability are key.

Laminated and coated structures—including PET/PE, PA/PE, and metalized films—are perforated with carefully calibrated force or energy to maintain layer integrity and barrier performance, crucial in modified atmosphere packaging (MAP) and high-performance industrial films.

In addition to polymer films, the systems also process thin aluminum foils, technical papers, and nonwoven webs, enabling applications in filtration, insulation, and breathable packaging.

Across all materials, Spark Machinery’s perforation solutions deliver repeatable accuracy, optimized gas transmission, and mechanical consistency, supporting high-quality results in packaging, technical, and industrial film production lines.

Get expert advice for your Perforation Needs

Choosing the ideal perforation machine can be a complex decision, given the diverse technologies and material considerations involved. To ensure you select the perfect solution for your specific needs, we invite you to a free, no-obligation consultation with our experts. Benefit from personalized insights into how the right hot, cold, or laser perforation technology can optimize your production, enhance product quality, and drive efficiency, ensuring a smart investment tailored to your success.

PERSONAL CONTACT

Looking for advanced industrial packaging or custom perforation solutions?

Discover how tailored airflow, moisture control, and material efficiency can elevate your logistics and product protection.

Contact our team today to explore custom-engineered perforation systems designed for your specific industry needs.

👉 Get in touch now or request a free consultation

DANA NURTAZINA

Commercial Export Office

+39 3405936421

d.nurtazina@sparkmachinery.com