Agriculture Plastic Film Perforation: Technology, Applications & Benefits

In modern crop production, mulching films are essential tools for optimizing field conditions and enhancing plant performance. Among these, perforated agricultural films play a pivotal role by combining the benefits of traditional mulch with enhanced environmental control. Precisely engineered perforations allow films to regulate soil temperature, balance moisture retention and gas exchange, and support robust crop growth throughout the season.

Spark Machinery is a specialist in technical perforation solutions tailored to the agricultural sector. With advanced engineering and meticulous process control, Spark Machinery enables production of perforated films that meet the exacting specifications growers demand for optimized mulching performance.

What Is Agricultural Plastic Film Perforation?

Perforated agricultural film refers to polymeric mulch films or horticultural covers engineered with controlled openings to enhance crop growth and microclimate management. These perforations, or holes, allow for regulated airflow, moisture exchange, and gas diffusion, improving plant health and productivity. While standard plastic mulch primarily preserves soil moisture and suppresses weeds, perforated variants introduce a level of environmental modulation crucial for sensitive crops.

The functionality of the holes depends on their size, distribution, and pattern.

Larger openings (macroperforations) facilitate ventilation and prevent excessive humidity accumulation, while smaller openings allow subtle gas exchange, reducing condensation and maintaining stable soil and canopy microclimates.

Types of Perforation Used in Agricultural Films

Agricultural film perforation can be categorized based on the size and function of the openings, which are tailored to specific horticultural and field crop applications.

Films with larger holes are typically used to promote ventilation and moisture control, allowing excess heat and water vapor to escape. This is particularly useful for multi-row crop covers, tunnels, and greenhouse applications, where preventing condensation and fungal growth is critical.

In contrast, smaller perforations are preferred when the goal is to maintain a stable microclimate, control humidity, and support soil moisture retention. The choice of hole size depends on the intended use: larger openings can aid in weed suppression and soil aeration for general mulching, while smaller openings optimize water management and create favorable conditions for sensitive crops.

Properly engineered perforation ensures a balance between environmental control and soil coverage, supporting healthy plant growth while maintaining the agronomic benefits of mulch films..

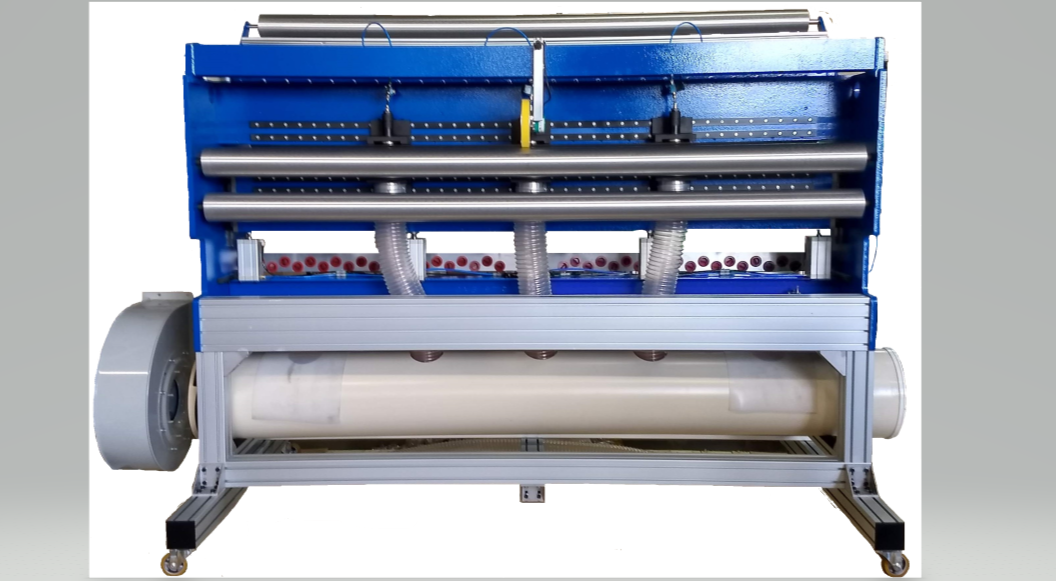

Our Macro Perforation Machines designed for mulching applications:

Materials Used for Perforated Agricultural Films

The performance of perforated agricultural films depends heavily on material selection, which influences durability, elasticity, and perforation quality. Low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE) are widely used due to their flexibility, tensile strength, and ability to produce clean, precise perforations. Typical film thickness ranges from 20 µm to 80 µm, with thinner films requiring higher elasticity and strength to prevent tearing during handling and perforation. High-density polyethylene (HDPE) and polymer blends are used when additional stiffness or puncture resistance is needed for heavier-duty applications.

Sustainability-focused materials, such as biodegradable polymers like PLA, PBAT, and starch-based films, are increasingly adopted to reduce plastic waste. These films maintain adequate mechanical strength for precise perforation while allowing controlled in-soil degradation, combining agronomic performance with environmental responsibility. Proper material selection ensures both reliable perforation and optimal microclimate management for crops.

The Role of Perforated Films in Crop Performance

Water Management and Irrigation Compatibility

Perforated agricultural films enhance drip irrigation efficiency by allowing water to infiltrate the soil directly through controlled openings, rather than remaining trapped on the film surface. This improves water distribution in the root zone and supports more uniform crop development.

By facilitating infiltration during irrigation and rainfall, perforated films also reduce surface pooling and minimize runoff, helping prevent water loss and localized waterlogging. At the same time, the film continues to limit evaporation, improving overall water-use efficiency and maintaining more stable soil moisture throughout the growing cycle.

Weed Suppression and Soil Health

Perforation patterns contribute to weed control by maintaining a continuous light barrier across the soil surface while limiting the open area available for weed emergence. With correctly engineered hole spacing and geometry, the film suppresses germination by reducing PAR (photosynthetically active radiation) transmission to the seedbed and physically restricting breakthrough points.

At the same time, perforated films help preserve nutrients by stabilizing soil moisture and reducing leaching. More uniform infiltration through the perforations supports controlled percolation, limiting nutrient washout (especially nitrogen) and maintaining a more consistent nutrient concentration in the active root zone.

Durability and Performance Factors

Perforated agricultural films are exposed to multiple environmental and mechanical stressors that affect their service life:

UV Exposure: Prolonged sunlight causes photo-oxidative degradation in polymers like LDPE, reducing tensile strength and elasticity. UV stabilizers (e.g., absorbers or carbon black) are essential to extend durability.

Temperature Stress: Thermal cycling—from cool nights to hot days—induces expansion and contraction, which can accelerate fatigue and cracking. Multilayer or co-extruded films generally perform better than monolayer LDPE.

Chemical Exposure: Contact with pesticides, herbicides, and fertilizers can accelerate polymer degradation, weakening mechanical properties and shortening film life.

Mechanical Wear: Wind, handling, abrasion, and installation stress can damage macroperforation edges, enlarging holes or causing tears.

Material Differences:

LDPE is flexible and easy to process, ideal for mulch films, but more prone to UV and mechanical degradation without stabilizers.

PP offers higher dimensional stability, chemical resistance, and thermal tolerance, making it suitable for harsher climates or longer-lasting applications.

Field conditions—such as intense sunlight, frequent irrigation, and heavy machinery—strongly influence the film’s durability in practice.

Applications of Perforated Agricultural Films

Perforated agricultural films are widely used across horticultural and field crop systems to enhance crop performance and protect plants. Common applications include mulching for vegetables such as onions, carrots, and spinach, weed control in open fields, and row covers or horticulture tunnels that support early-season crops and improve microclimate conditions.

A notable example is the use of perforated covers in banana plantations. In regions with volcanic activity, films with smaller perforations are preferred to protect fruit from harmful volcanic gases while still allowing limited airflow. In other regions, larger perforations are used to provide ventilation and shield the plants from insect pests, demonstrating how perforation size can be tailored to specific environmental challenges and crop protection needs.

The growing adoption of perforated films is reflected in broader market trends: although food packaging remains the largest segment for PE perforated films, agricultural applications such as mulch films and greenhouse covers are significant contributors to market demand, driven by the need for enhanced microclimate control and improved crop outcomes.

Benefits of Precision Perforation for Agricultural Film Manufacturers

-

Accurate perforation allows films to regulate temperature, humidity, and airflow, supporting stronger plant growth, earlier development, and higher yields.

-

Controlled hole size and spacing create a stable environment around roots and canopy, balancing soil moisture, gas exchange, and heat for sensitive crops.

-

Precisely perforated films reduce evaporation and allow targeted water infiltration, minimizing water waste and improving irrigation effectiveness.

-

Consistent perforation reduces excess material usage, lowers waste during production, and supports environmentally responsible agricultural practices.

Spark Machinery’s Expertise in Agricultural Film Perforation

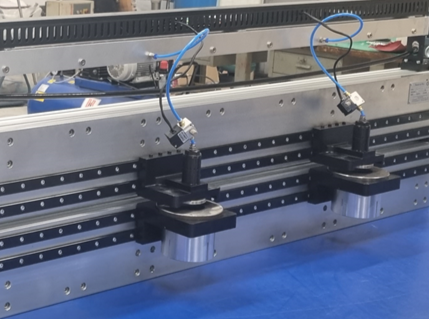

Macro perforation is a core technology in Spark Machinery’s portfolio.

By creating precisely sized and evenly spaced larger holes, these systems optimize ventilation, water infiltration, and soil aeration—key factors for healthier crops, improved root oxygenation, and effective weed control.

With many years of engineering expertise in macro perforation, Spark Machinery delivers systems that ensure consistent hole size, spacing, and quality, even at high production speeds. Our solutions are customizable to film type, thickness, and line speed, allowing manufacturers to achieve repeatable, high-performance films tailored to specific crops and environmental conditions.

By combining precision engineering, process optimization, and long-term support, Spark Machinery positions itself as a true partner for agricultural film producers, enabling both operational efficiency and superior agronomic outcomes.

Get expert advice for your Perforation Needs

Choosing the right macro perforation system can be a critical decision, given the variety of materials, line speeds, and hole pattern requirements. To help you make the best choice, we offer a free, no-obligation consultation with our technical team. Gain personalized guidance on how a customized macro perforation solution can enhance production efficiency, ensure consistent hole quality, and optimize film performance—delivering a smart investment designed to meet your specific manufacturing goals.

PERSONAL CONTACT

Looking for advanced industrial packaging or custom perforation solutions?

Discover how tailored airflow, moisture control, and material efficiency can elevate your logistics and product protection.

Contact our team today to explore custom-engineered perforation systems designed for your specific industry needs.

👉 Get in touch now or request a free consultation

FEDERICA CANTAGALLI

Commercial Export Office

+39 3420324381