Macro Perforation: Technology, Applications and Benefits

What is Macroperforation?

Macro perforation refers to the intentional formation of relatively large holes (typically >100 µm) in films, laminates, or papers to modify material permeability and airflow. Usually produced via mechanical methods, these perforations enable controlled gas exchange, moisture release, or ventilation.

In packaging, macro-perforated films optimize respiration rates for fresh produce or allow steam release in ready-meal applications. In industrial uses, they enhance drying, filtration, and ventilation processes. Thus, macro perforation is a critical material-engineering feature for tailoring performance and functionality in diverse processing and packaging systems.

How does Macro Perforation work?

In mechanical macro‑perforation, the size and arrangement of the holes are tailored to the material’s function: larger apertures increase airflow, drainage, or product respiration, while smaller macro openings allow moderate gas exchange without compromising strength. Patterns are customized for different applications—uniform grids for fresh produce, edge slots for pouches, or distributed holes in mulching films to support soil ventilation and moisture control. The mechanical method ensures consistent hole geometry, high-speed production, and reliable performance across food, industrial, and agricultural packaging.

Benefits of Macroperforation

-

Macro‑perforated films allow air to flow freely, reducing condensation and heat buildup. Example: Fresh produce packaging uses evenly spaced perforations to maintain airflow, preventing spoilage and maintaining visual quality during transport.

-

Perforations enable controlled moisture release, balancing humidity inside packaging. Example: Bakery and snack packaging employs macro‑perforated films to prevent sogginess while retaining product freshness.

-

By regulating gas exchange and moisture, macro‑perforation slows degradation of sensitive products. Example: Fruit and vegetable packaging reduces ethylene accumulation, extending shelf life during distribution.

-

Uniform hole patterns support consistent ventilation and protection across the entire package. Example: Palletized industrial goods wrapped in macro‑perforated stretch films avoid moisture buildup, reducing the risk of product damage.

-

Patterns and hole sizes can be tailored to specific needs, from fresh food to agricultural films. Example: Mulching films with distributed perforations allow soil aeration and water drainage while protecting crops.

This combination of functional benefits makes macro‑perforation a versatile solution for food, industrial, and agricultural packaging applications.

Industries and Applications of Macro Perforation

Macro‑perforation is widely used across industries where controlled airflow, moisture management, and product protection are critical. Key applications include:

-

Fruits, vegetables, and leafy greens are commonly packed in macro‑perforated films to regulate respiration, reduce condensation, and extend shelf life. Bakery products also benefit from perforations that prevent sogginess while maintaining freshness.

-

Industrial goods and palletized products use macro‑perforated stretch films to improve ventilation, reduce moisture accumulation, and enhance transport safety by maintaining product stability during shipping.

-

Perforated films for soil covers allow water drainage, gas exchange, and root aeration, supporting crop growth while protecting the soil and plants.

-

Other applications include medical and industrial packaging where controlled permeability is needed, such as sterile barrier films or breathable pouches.

Macroperforation vs. Microperforation

| Feature | Comparison |

|---|---|

| Hole Size | Micro‑Perforation: very small (<100 µm) Macro‑Perforation: larger (>100 µm) |

| Precision | Micro‑Perforation: high precision, often laser or needle Macro‑Perforation: moderate precision, mainly mechanical punching or die-cutting |

| Intended Use | Micro‑Perforation: gas exchange without compromising barrier properties Macro‑Perforation: ventilation, drainage, moisture release |

| Suitable Materials | Micro‑Perforation: thin films, laminates, foils Macro‑Perforation: films, foils, multilayer packaging, stretch films |

| Product Impact | Micro‑Perforation: maintains product protection; minimal visual impact Macro‑Perforation: enables significant airflow or moisture control |

| Applications | Micro‑Perforation: fresh produce with low respiration, modified atmosphere packaging, sterile barrier films Macro‑Perforation: fresh produce, bakery, pallet wrapping, mulching films, industrial ventilation packaging |

This table highlights how the two technologies serve complementary roles: micro‑perforation for precise, subtle permeability, and macro‑perforation for functional openness and airflow.

Industrial use cases: How our customers benefit from Macro Perforation

Case Study: Zoloplast – Expanding Packaging Capabilities with Spark Machinery

Company Overview

Zoloplast, based in Valencia, Spain, is a packaging specialist with over 25 years of experience. The company designs and manufactures custom bags, presentation boxes, and films for diverse sectors including food, textiles, and industrial packaging. Zoloplast emphasizes high-quality materials, sustainable solutions, and innovative designs that reflect their customers’ brand identity.

Challenge

As Zoloplast expanded its product lines, including fresh food packaging, flow packs, and compostable films, the company needed reliable machinery to produce high-quality macro-perforated films for ventilation, moisture control, and extended product shelf life.

Solution

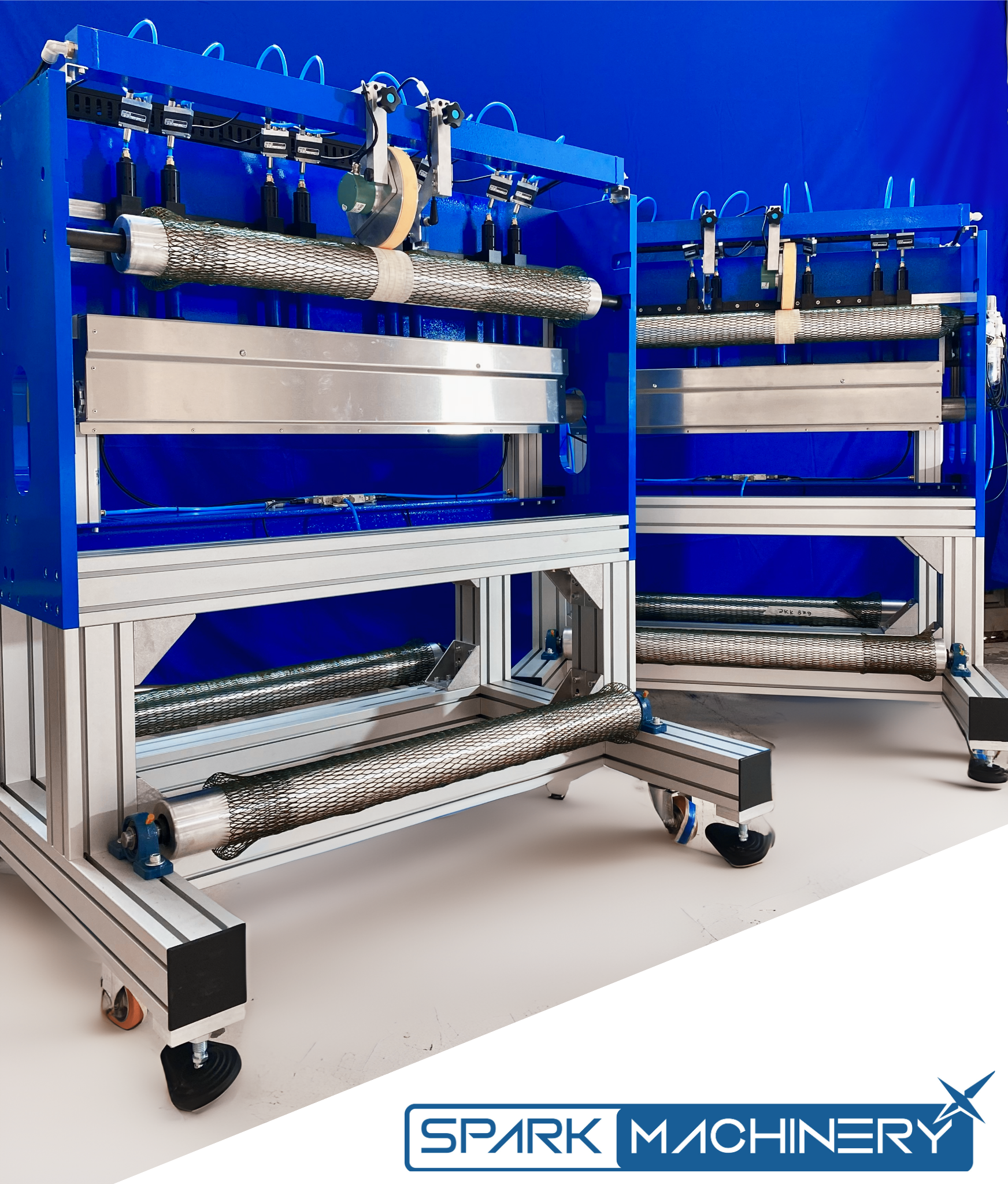

Zoloplast had previously invested in one Spark Machinery macro-perforation unit, which proved highly effective in delivering consistent hole patterns, precise mechanical perforation, and improved film performance. Satisfied with the results, Zoloplast later purchased two additional Spark Machinery units, a macro-perforator with soundproofing and a hot needle micro perforator with suction hood and fume-filter system to meet growing production demands and diversify its packaging offerings.

Need expert advice on Macro Perforation?

Choosing the ideal macro-perforating machine can be a complex decision, given the diverse technologies and material considerations involved. To ensure you select the perfect solution for your specific needs, we invite you to a free, no-obligation consultation with our experts. Benefit from personalized insights into how the right hot, cold, or laser perforation technology can optimize your production, enhance product quality, and drive efficiency, ensuring a smart investment tailored to your success.

PERSONAL CONTACT

Looking for advanced industrial packaging or custom perforation solutions?

Discover how tailored airflow, moisture control, and material efficiency can elevate your logistics and product protection.

Contact our team today to explore custom-engineered perforation systems designed for your specific industry needs.

👉 Get in touch now or request a free consultation

DANA NURTAZINA

Commercial Export Office

+39 3405936421

d.nurtazina@sparkmachinery.com